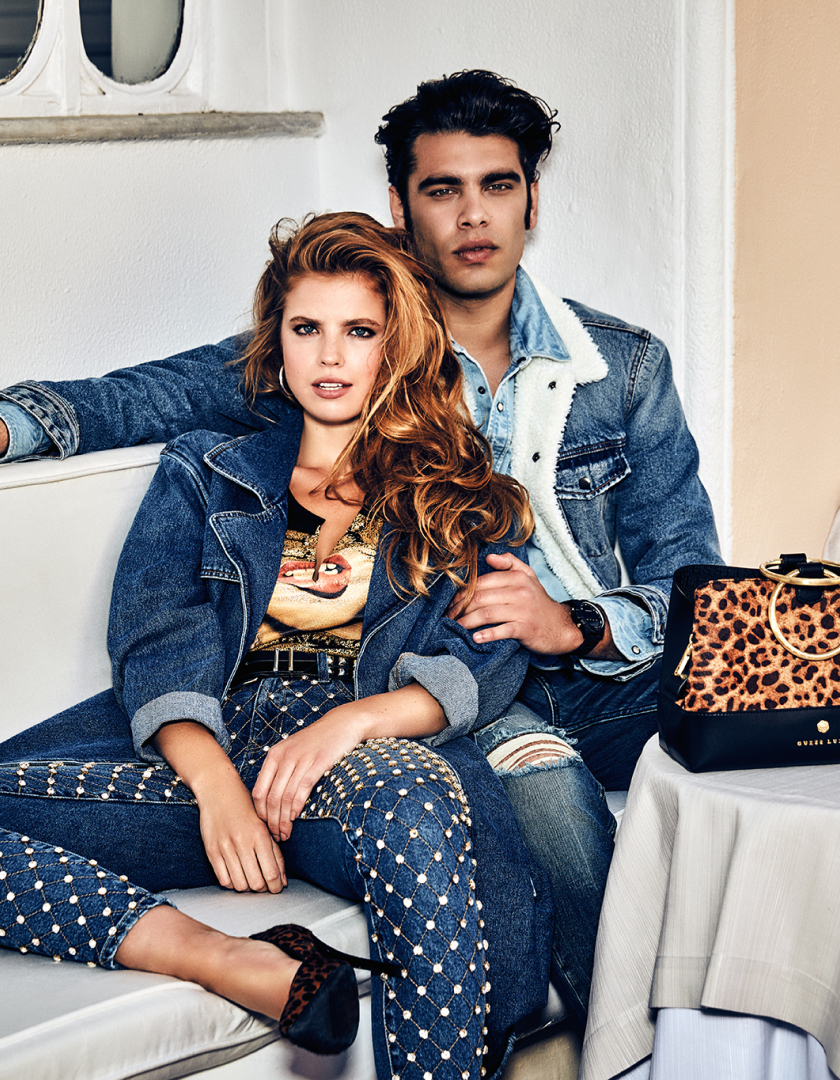

Fast Fashion

“When you’re talking about introducing 600 styles for each season in approximately 30 different factories, the process becomes very complex. There were many errors and communication failures between different areas, which generated quality issues and delays.”

Luis Hernández, Chief Operating Officer at Capa de Ozono, recalls that everyday operations at the Mexican fashion footwear brand became difficult to manage several years ago. Seeking ways to reduce time to market, develop a more robust product development process and centralize product information, Capa de Ozono began looking for a Product Lifecycle Management (PLM) solution.

“We focus on being a fast fashion company, which means we have to get on board with new developments and designs that are appropriate for the market in the fastest possible way,” explains Stefan Hromatka, CEO of Grupo Acritus, Capa de Ozono’s parent company. “The biggest challenge we have, is to identify new trends on time and drop the trends that no longer work.”

Today, with Centric PLM in place, Capa de Ozono has improved product development time by 20%, been able to launch new products on schedule 90% of the time and has doubled its number of collections, without needing to increase design and development staff.

Why did Capa de Ozono decide to make the leap with Centric PLM and how has it changed the way people work every day at the company?

Rapid Growth

Capa de Ozono was founded in 1992 and is headquartered in León, Guanajuato, the capital of the Mexican footwear industry.

Capa de Ozono designs, manufactures and sells footwear, mainly for the teenage and young adult market, and is one of Mexico’s largest fashion footwear retailers. Capa de Ozono sells through a network of 235 branded stores in 50 cities and has over 300 wholesale clients as well as a popular online channel. The company has grown significantly in recent years.

“When I arrived, we had 80 stores and today we have 180 owned stores and 50 franchises,” says Stefan Hromatka. “We almost doubled the business in the last five years. Last year we acquired two other brands: a footwear brand called Dorothy Gaynor and a swimsuit brand, Zíngara.”

Together, Capa de Ozono, Dorothy Gaynor and Zíngara make up the Grupo Acritus group. Acquiring the new brands expanded the business by approximately 46%.

Keeping up the Pace

In order to keep producing affordable, fashionable footwear, Capa de Ozono is pursuing a fast fashion strategy. The company began looking for ways to reduce time to market and develop a more robust product development process that would ensure quality in high volume production.

Managing large amounts of product-related information using spreadsheets, email and various documents became overly complex and errors crept in. Communication sometimes broke down, resulting in delays and quality control issues.

As Delia Macias, Senior Design Manager at Capa de Ozono explains, “The product information was created and passed on to many different departments that would make their own changes. Version control became very difficult and complicated.”

“As the company grew, we saw the need to adapt to new processes,” she continues. “It was then that we realized that we needed a PLM solution.”

If the Shoe Fits

Capa de Ozono made contact with Centric Software, who had established a Latin American office in Mexico City in 2015. Following positive references from other customers in the region, successful product demonstrations and a PLM workshop, Capa de Ozono decided that Centric PLM was the perfect fit.

Capa de Ozono selected Centric PLM on the basis of its footwear expertise, the solution’s flexibility and its ability to completely cover the entire product lifecycle.

“We chose Centric because it was the solution that we could configure to best fit our needs,” explains Delia Macias. “It’s like a tailored suit.”

As Luis Hernández adds, “We thought that the ability to manage new product development and introduction projects using the calendar management module was a very interesting feature. It’s extremely useful for managing the implementation schedules of new products.”

Striding Into the Future

Capa de Ozono implemented Centric PLM within budget and on schedule and uses it to run the entire product development process.

Capa de Ozono now has a firm foundation for integrating existing processes and systems with PLM, as well as plans to connect Centric PLM with their in-house ERP system to further aid the seamless delivery of products from design conception, right through to manufacturing and distribution. In order to make sure that designers could take advantage of Centric’s Adobe Connect capability, the company standardized their design software to Adobe Illustrator.

“My whole team uses it,” says Delia Macias. “We have reduced the average amount of time we spend on product development by 20 percent.

Centric PLM gives me comprehensive and extensive visibility of each collection and better control, since we have everything we need to develop a product on a single platform.

“The process for designers is made so much simpler.”

Capa de Ozono is expanding the use of Centric’s Calendar module to enhance specific quality control measures for footwear. Production departments are now able to use information generated by design and development teams to validate products in advance, assess the feasibility of manufacturing new products and improve product quality. The company plans to add a group of manufacturing suppliers to Centric PLM so that they can share technical information and improve the quoting process. “We can now reach levels of 90 percent compliance with the planned dates for launching new products to the market,” says Luis Hernández. “We have also been able to double the number of collections we launch.”

As Stefan Hromatka concludes, “Centric PLM helps us as managers to gain more visibility and a much more controlled process and users can free up time to focus on their designated roles – speeding up product development. As a crucial part of our omnichannel plans, Centric will be the database for the master data of all our brands in the future.”

“We consider Centric PLM to be a fundamental part of our growth strategy.”

New to Centric PLM? Learn more

What is Centric Pricing & Inventory? Learn more

What is Centric Market Intelligence? Learn more

Product Matching Software Learn more

Centric Visual Boards Learn more