Ready for Change

“We wanted to introduce Centric PLM as the core single source of truth, and to make this happen, it was important to get rid of Excel and to work within a common platform.”

Valentin Lecerf, IT Product & Supply Application Manager at Camaïeu, acknowledges that working with more traditional methods such as spreadsheets didn’t support the volume and accuracy of data required for a leading womenswear brand.

What were the results of Camaïeu’s Product Lifecycle Management (PLM) project?

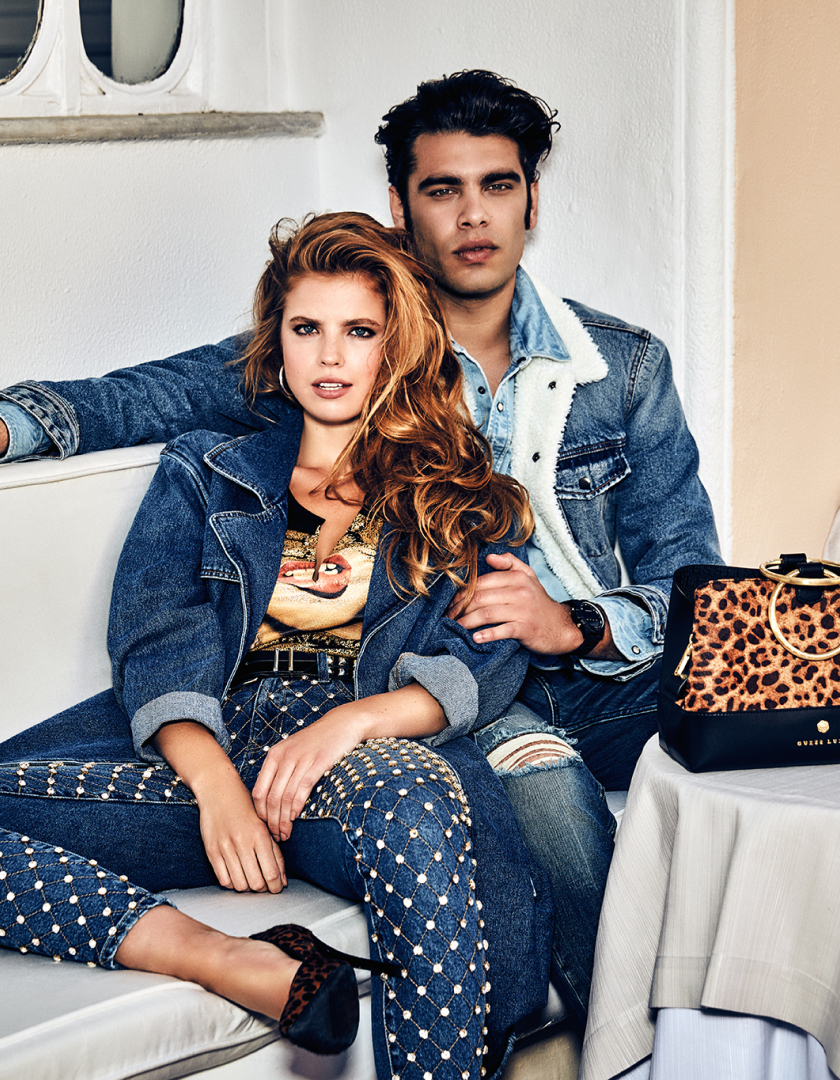

Leading French Brand

Camaïeu is the leading French women’s ready-to-wear brand and has approximately 900 stores in 23 countries.

Sandrine Guichard, Application Project Manager at Camaïeu shares the brand’s primary reason for selecting a digital transformation solution, “For us, the goal is to become more agile when developing collections which, in turn helps us make sure that our spin on fashion trends carries through from design concept to production to stores.”

“We wanted to establish a more synchronized and collaborative way of working.”

Selecting Centric PLM

Camaïeu introduced Centric PLM to empower employees across all departments – from IT to pattern cutting – to operate in real-time with one single source of the truth.

“We were looking for a PLM solution to centralize product data and make this information more reliable,” explains Lecerf.

He describes the transformation process, “To start with, we cleaned the data by standardizing all Excel files, which were then ready to be imported in C8 PLM.”

“Today, data is entered into Centric PLM, sent to our ERP and then rolled out within the entire system.”

Centric PLM ensures all information is reliable, secure and unified.

Agile Deployment

Centric PLM was delivered completely within scope, schedule and budget in just six months, and user adoption has been excellent. Camaïeu put much of this down to Centric’s Agile Deployment methodology.

“It allows you to test and modify your configuration so you can adapt Centric PLM to your needs,” says Esther Ghestem, Buyer at Camaïeu.

Transforming Pattern Making

Centric PLM plays a pivotal part for the pattern making team, handling complex technical data including sizing and points of measure. This ensures an accurate and comprehensive tech pack can be created, faster than previously.

Marie-Christine Desjardins, Head of Pattern Making at Camaïeu shares more results of Centric PLM for her team, “The main benefits for the pattern making team are schedule management and better anticipation of workloads.”

We also now have a unique, global view of the collection from design all the way through to production managed by our buying offices.

Closer Collaboration

Reflecting on how far the project has come, Desjardins says, “I am extremely proud that we have managed to bring the Product and IT teams closer together and that today we have a full understanding of our product needs, and that they are able to adapt our tools very closely to our objectives.”

“Centric is very knowledgeable of the fashion industry and fashion processes. The next step will be to introduce it to our suppliers,” concludes Guichard.

New to Centric PLM? Learn more

What is Centric Pricing & Inventory? Learn more

What is Centric Market Intelligence? Learn more

Product Matching Software Learn more

Centric Visual Boards Learn more