Made to Measure (M2M): Personalization Delivered by You

Made to Measure (M2M) is…..The Future. Anyone tired of having to get new clothes altered before you can wear them? Or ever seen a cool product but were not into the colors offered?

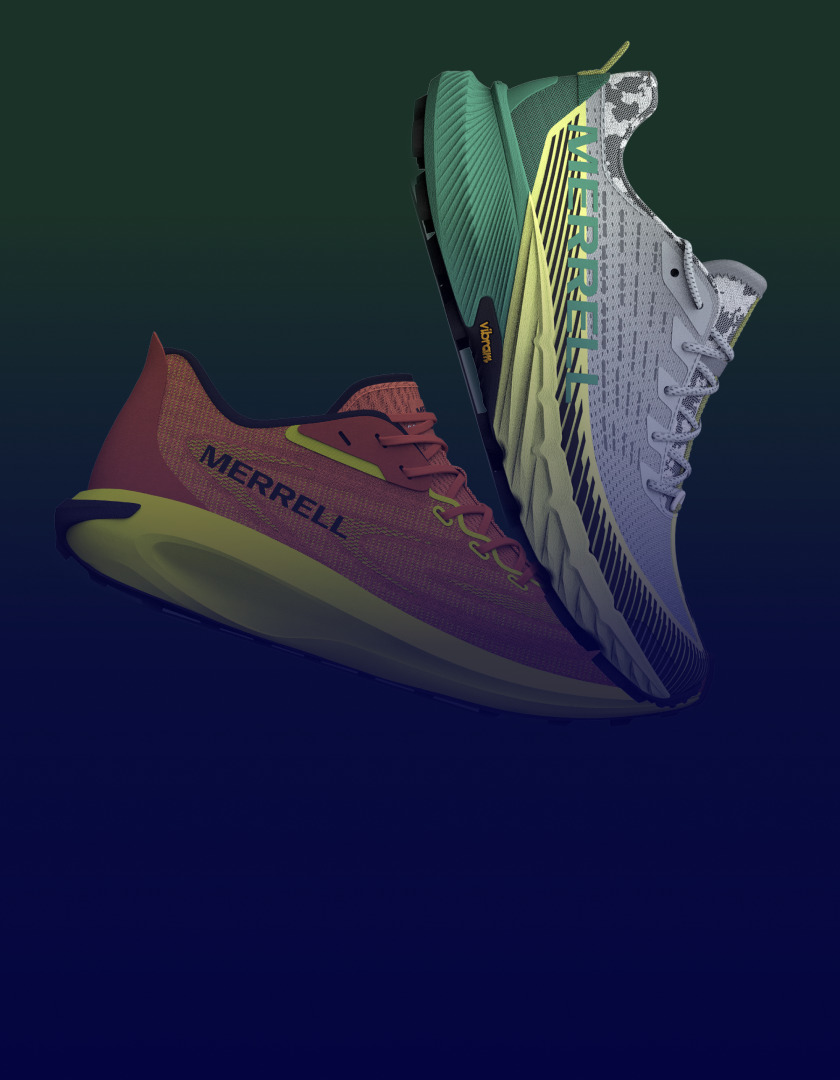

Fashion and apparel companies that can master the art of developing, producing and delivering mass customized goods will have a tremendous business opportunity as the demand for affordable, customized clothing and footwear is rising. M2M appeals to a new breed of consumers who are looking for properly fitting and personalized garments. And this is especially desirable to Millennials and Gen Z, who really want what they want and are not willing to compromise.

The M2M Challenge

M2M is easier said than done. While traditionally produced, mass market goods mean managing hundreds or thousands of SKUs (stock keeping units) at any given time, personalized garments would increase that number exponentially as each M2M order is, effectively, its own SKU. An SKU requires a lot of information like BOM, measurements, colors, materials, costings, quality standards, etc. M2M focuses on industrializing the personalization process on a mass scale.

There is no way to manage M2M on any kind of scale without a PLM solution as the foundation. The typical product development challenges of having one unique set of information, respecting costing targets, team & supplier collaboration, a fast time to market, etc. are amplified due to the fact that a collection of base products must still be created and developed (branded, marketed, sold and materials procured) but also each individual garment must be managed as its own unit from a development and production standpoint. M2M is a happy medium between one-off garments and mass production. Again, PLM is obligatory.

PLM is the backbone technology that drives all product-related activities from concept to retail. PLM improves collaboration, reduces errors and costs and speeds time to market resulting in streamlined operations. Having one set of unqiue, actionable data is key.

Here are top 3 reasons why Centric PLM helps enable a M2M product lifecycle process:

Centric PLM holds information about all of the various components that are needed to develop and produce a product such as material libraries, colors, CAD files, measurements, testing details, construction instructions, etc. These components can be pulled together quickly to put an individual spec pack together for a given order. For M2M or mass production, the benefit is the same; yet in the case of M2M, the combination of components constantly varies so centralizing the base component information is imperative or clean, fast execution is impossible. It is the like taking the challenges of mass production and exponentially multiplying the level of coordination needed.

When production, linking the complete spec pack for an individual product to other business systems such as ERP, CAD, DAM, PIM, etc. is also key. BOM, patterns and production routings, delivery deadlines, inventory levels and more are needed to move into production. Centric PLM generates and also centralizes this information. Users can manage these files, even sizing information, for each M2M product by pulling from libraries. Centric PLM can also connect with different CAD systems to automatically make general measurements and customized sizing.

With Centric PLM, manufacturers can efficiently manage color, size and fit by predefining product parameters early in the collection process. For example, each component of Shirt model 123 will be available in 10 colors allowing consumer to mix and match (blue sleeves with a white body and a green collar, say). By automating the available options and combination of options on a single and shared platform updated in real time, Centric PLM helps teams avoid errors and miscommunication with partners, speed order entries and better allocate stocks and ultimately better ensure store replenishment.